Feed management and administration

Logistics: Purchased feed is generally stored in a dry, elevated, and central location. From there, feed bags are transported to each pond. Most farmers have a set feeding schedule, but make adjustments based on shrimp feeding behavior and observed feed left in check trays. Feed distributors will also often supply farmers with suggested feeding schedules or a logbook to assist with feed conversion rations and other calculations. Logbooks are also used to keep a record of feed volumes and other measurements.

Feeding: Manual, semi-automatic, and fully automatic feeding methodologies are currently used in the industry. Manual feeding involves farm staff throwing scoopfuls of feed while walking around the perimeter of the pond or while floating on a raft moving along a grid system in interior edges of the pond. This is usually done for the first 30 to 40 days of a crop cycle after ponds are stocked with post-larvae in stages 8 to 12. Thereafter, farmers either continue to feed manually or switch to semi-automatic feeding which involves the use of auto-feeders attached to retractable rafts or feed bridge walkways. . The semi-automatic feeders require feed settings to be manually adjusted while the feed volumes and frequencies of the fully automatic feed systems can be remotely or acoustically controlled according to shrimp behaviour and the farmers’ requirements. Auto-feeders are a proven method that reduces shrimp size variation, FCR values, that also saves costs.

Observation: Before feeding, farm staff perform visual inspections of feeding behavior. To do this, they use ‘check-trays’–a small round or square metal frame fitted with a nylon sheet that is submerged onto the pond floor. These trays are carefully lifted out of the water with an attached rope, and farmers can then inspect the shrimp for uneaten pellets, fecal color, and fecal length. Based on these observations, farmers will adjust their feeding plans accordingly, either by adjusting the settings on the auto feeders, or by communicating their observations to the staff in-charge to amend the new feeding plan. This information is usually related verbally or via text. Farmers vary the frequency of feed administration according to the frequency of visual inspections. Manually fed shrimp are inspected between 1 to 2 hours after each feeding and between 2 to 5 times a day. Semi- or fully automatically fed shrimp are inspected between 4 to 6 times a day.

Feed preparation: Traditionally, farmers administer dry-uncoated feed into ponds. Nowadays, many prefer to add an extra coating of liquid pre- and probiotics, other additives, attractants and/or other nutritional products. These liquid coating materials are prepared in advance and then either manually or mechanically mixed with dry pellets to coat dry pelleted feed. Thereafter, the feed is weighed according to the managers feed calculations and is then transported to each pond.

Significance: Feeding on time and in the correct volumes is crucial to efficient growth as inefficient feed conversion ratios implies inefficient resource use and lost profit margins.

Pond fertilization: As an additional source of nutrition, farmers increase pond zooplankton populations and microbial communities by administering a variety beneficial liquid solutions. This is done by aerating a mixture of bacteria, seawater, and other ingredients over a day or two. Once fermented, the liquid is then added into the ponds manually or via a pipe between the aerated container and targeted pond.

Below is a country comparison on feed management and administration tools and methods

DATA overview

| www.shrimpfarm.tech by HATCH | Indonesia | India | Ecuador | Thailand | Vietnam | China |

|---|---|---|---|---|---|---|

| Check tray used and observation method Yes or no, manual or digital |

Yes, manual | Yes, manual | Yes, manual | Yes, manual | Yes, manual | Yes, manual |

| Check tray location Suspended from rope grid or suspended from feed bridge |

Suspended from feed bridge | Suspended from rope grid | TBC | Suspended from feed bridge | Suspended from feed bridge | Suspended from rope grid |

| Check tray shape Round or Square |

Square | Round | Round | Square | Square | Round |

| Physical documentation of check tray observations None documented, uncommon or routinely |

None | Uncommon | TBC | Uncommon | Uncommon | None |

| Nutrition source Bio-floc, dry or liquid coated pelleted feed |

Dry or liquid coated pelleted feed | Dry pelleted feed/td> | Dry or liquid coated pelleted feed | Dry or liquid coated pelleted feed | Dry or liquid coated pelleted feed | Dry pelleted feed |

| Method used for coating pelleted feed with fermented liquids or liquid probiotics Manually or with electric mixer |

Electric Mixer | N/A | Electric Mixer | Manually and electric mixer | Manually | N/A |

| Pellet weighing None, mechanical, semi-digital or automatic weigh scales |

Semi-digital weigh scale | Semi-digital weigh scale | None | None | Mechanical weigh scale | Semi-digital weigh scale |

| Method of feed administration By hand, boat and bucket or auto-feeders |

Auto-feeders | By hand or Boat and bucket | Boat and bucket or auto-feeders | Auto-feeders | Auto-feeders | By hand or boat and bucket |

| Location of auto-feeders Floating (fixed or on string) or on feed bridges |

Feed Bridges | N/A | Floating on retractable ropes | Feed bridges or floating on a retractable ropes | Feed Bridges | N/A |

| Control of auto-feeder settings Manually, semi-digitally, or remote-controlled |

Manually controlled | N/A | Semi-digital or remote controlled | Manual or semi-digital controlled | Semi-digitally controlled | N/A |

| Pond area covered per individual auto-feeder m2 |

2625 | N/A | Undetermined | 3845 | 2646 | N/A |

| Added nutritional source Onsite fermented fertilizing or biofloc, Uncommon or common |

Onsite fermented fertilizing, common | Neither are common | Onsite fermented fertilizing, common | Onsite fermented fertilizing, common | Onsite fermented fertilizing, common | Neither are common |

Summary

Before determining the amount of feed to administer, every farmer uses check trays to visually inspect feed consumption rates. There are instances in Ecuador where farmers use a PVC pipe to observe feeding behavior, amount of uneaten feed, and overall shrimp health (see images below). Farmers in Indonesia and China do not keep a written or digital record of these daily observations while very few supervisors and managers in India, Thailand, and Vietnam receive text of a picture of hand written results on the percentage of leftover feed in the check trays after inspection.

Administering coated feed with liquid probiotic additives is popular among farmers in Indonesia, Ecuador, Thailand, and Vietnam, though it appears that more farmers prefer to administer un-coated dry feed in India and China. To coat feed, small Vietnamese farms mix the feed by hand. Other farmers in Indonesia, Thailand, and Ecuador use mechanical mixers that are similar to what construction companies used to mix concrete in.

All farmers who manually administer and/or coat their feed use weighing scales to measure the amount of feed. The design and model of these scales vary across farms and countries. It is worth nothing that none of these farmers are advanced and connected to any software while most of the farmers in Thailand and Ecuador that use auto-feeders do not weigh their feed. They simply open and pour the entire 25 kg feed bag into the auto-feeder holding containers.

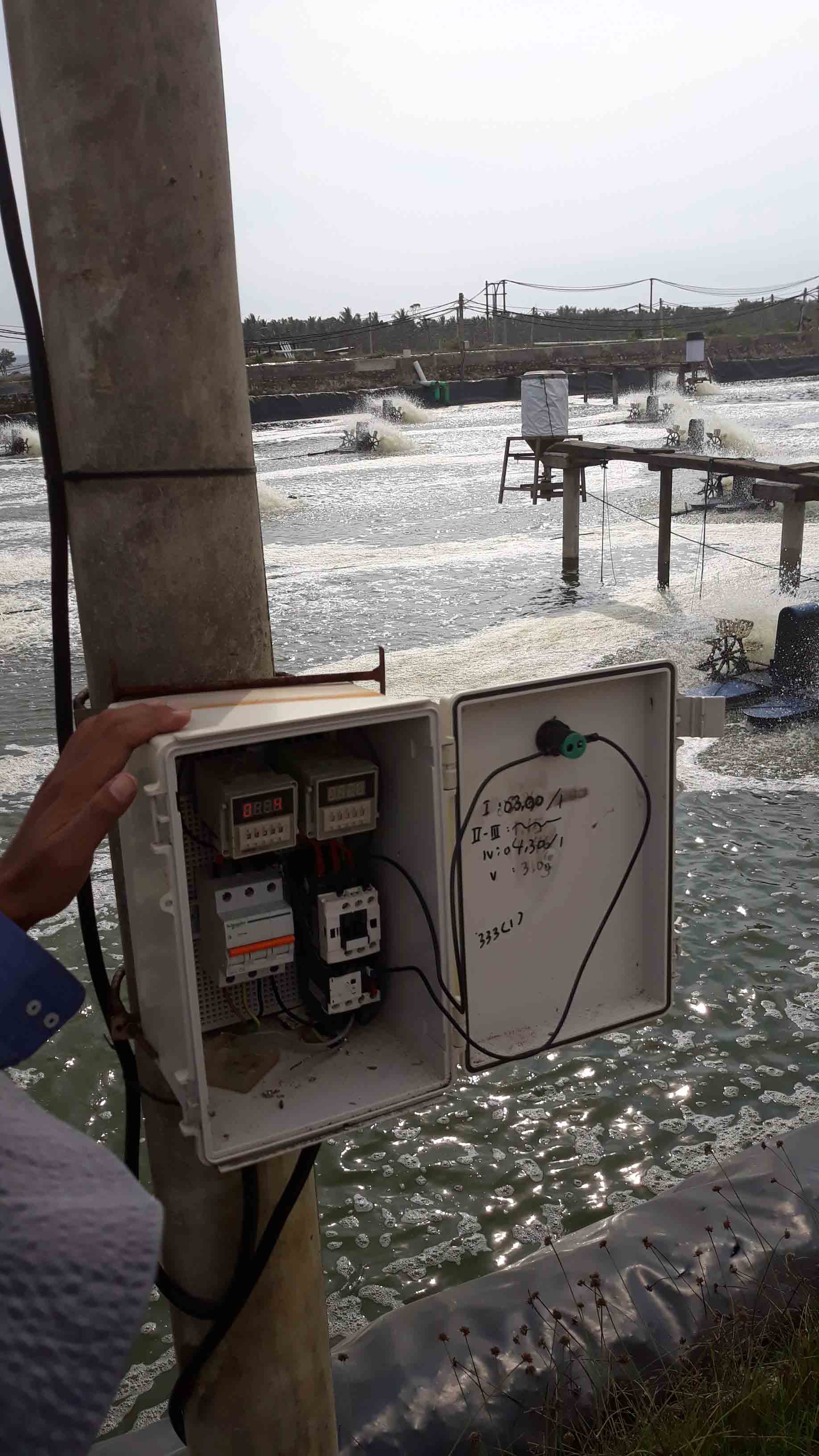

Except for shrimp farmers in India and China, most use auto-feeders. Interestingly, many Chinese fish farmers use auto-feeders while shrimp farmers have not yet adopted this feeding method. Farmers in Ecuador and Thailand position their auto-feeders on floating rafts that can be maneuvered using retractable rope system so that farmers to refill the feed. Feeders are then released from the side of the ponds to continue administering feed. Positioning auto-feeders further away from pond dykes promotes even feed distribution and facilitates lower competition for feed among the shrimp. Alternatively, farmers in Indonesia and Vietnam will build extended walk-ways (feed bridges) through the middle of ponds for them to attach their auto-feeder.

Remotely and acoustically controlled auto-feeders are most common types of feeders found in Ecuador while semi-automatic feeders are common in Thailand, Ecuador, and Vietnam. Manually controlled auto-feeders are also used in Indonesia and Thailand.

Pond water fertilization with fermented beneficial probiotics is a common practice among farms before stocking ponds with post-larvae across all countries. However, few farmers in India and China would continue this practice after stocking their ponds. In contrast, most farms in Indonesia, Ecuador, Thailand, and Vietnam facilitate frequent pond fertilizing by placing the aerated tanks adjacent to the ponds for easy transfer of fermented liquids and fertilizers. Periodically fertilizing ponds stimulates natural zooplankton blooms and promotes beneficial symbiotic relationships to stabilize and maintain good water quality in addition to providing extra nutritional sources for shrimp. This biomimicry practice in aquaculture has been trademarked as “Aquamimicry” and is proven to be successful in Thailand, Indonesia and Ecuador. Other countries that this practice has grown in popularity is Belize, Malaysia, Mexico and Singapore. Please find pictures of “on-site fertilization” at the bottom of this page.

Innovation opportunities

Since water in shrimp ponds is too deep and turbid for farmers to view shrimp feeding behaviour (unlike the water in salmon farms), most shrimp farmers are limited to manually checking the amount of feed left in the check trays and the gut of shrimp. Some companies have started to integrate acoustic sensors with their auto-feeders. These sensors listen to shrimp feeding behaviour and determine the time and manner the auto-feeder should administer feed into the pond.

Feed contributes the most to farmers’ production cost. As such, an auto-feeder that responds in real-time can help farmers to avoid wasting feed and prevent overloading ponds with excess nutrients. However, these acoustic feeders are still expensive for most farmers and we hope to see more affordable and accessible options for farmers in the future..

Normal, non-remote auto-feeders require human intervention to pre-set the time and frequency of feed administration. Farm managers report that staff may find it challenging to operate the auto-feeders or that their staff only set the auto-feeder once daily as opposed to multiple times per day according to observation of feeding behavior. To improve the efficiency of feed administration, there is an opportunity to provide farmers with an additional solution to manage their existing auto-feeders. Farmers mentioned that their adjusted settings on auto-feeder control panels are based on their calculations of predicted feeding rates at different periods throughout the day. This is where errors can occur due to ineffective communication between staff. Farmers who manually adjust auto-feeders settings suggest that they should only enter the correct feeding rate value into a device or on the control panel once for the auto-feeder to operate accordingly without additional adjustments. If similar solution could be adopted to existing manually adjusted auto-feeders, this is one example of innovation may simplify operations and reduce the risk of ineffective feed administration.

Another opportunity lies in the prediction of future feed requirements which can reduce the cost for farmers to purchase feed by ordering in advance on better terms.

Sensors to measure shrimp biomass, movement, and feeding behaviour that are integrated with a management platform would be revolutionary in helping farmers better plan and predict feed volumes and schedules.

These new tools should be simple to use, easy to install, durable in corrosive saline conditions, and compatible with smartphones.

Check tray types

Check tray location

Feed consumption measuring techniques

Feed calculation

FEED Storage

Fermentation of liquid probiotics over dry pellet feed

FEED Transport

Feeding Method

Auto-feeder types and positioning

Auto-feeder parts

Auto-feeder control

ON-Site Fertilisation